The pressure of modern people is doubled, and comfort and taste have become the primary requirements of contemporary people for bathroom space. With the continuous development of the overall bathroom market in China and the improvement of consumer purchasing power, suppliers are also gradually improving their competitiveness, trying to bring people an ideal living space through faster distribution and installation speed and higher quality bathroom space. experience.

In order to increase the speed of internal logistics and keep up with the pace of enterprise expansion, the enterprise sought out more efficient and convenient logistics solutions.

Client Background

The customer belongs to the overall bathroom equipment supplier, has advanced technology and research and development capabilities, and has been contributing to the innovation of bathroom products for many years. With the expansion of business, the need to improve the efficiency of warehousing and logistics has become increasingly prominent.

In order to increase the speed of internal logistics and keep up with the pace of enterprise expansion, the enterprise sought out more efficient and convenient logistics solutions.

Project Difficulties

Difficult to meet high throughput requirements

The storage rate cannot meet the development needs

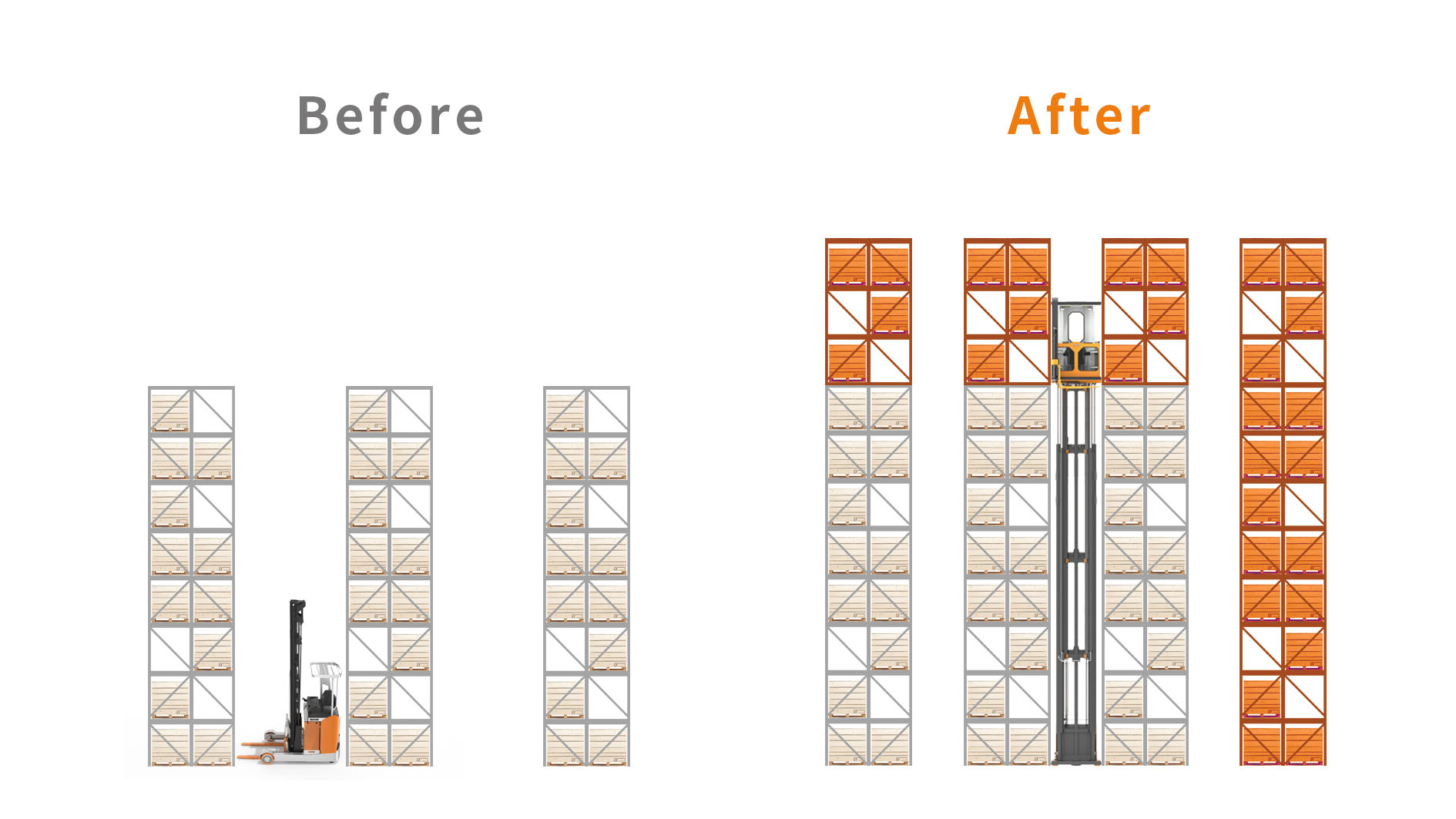

The height of the original shelf is low, and the space in the upper part of the warehouse is not effectively utilized. The company wants to upgrade its intensive storage, but because the company is located in a coastal city, the ground is under too much pressure when using heavy equipment, which may lead to ground subsidence, and the transformation of the storage area encounters difficulties.

Personnel safety is not guaranteed

There are no guide rails or other forklift operation auxiliary devices installed on the bottom of the shelf, and the forklift driving into the depth of the shelf for access operations is likely to collide with the shelf, which cannot effectively avoid safety accidents.

Zowell VNA forklift solution

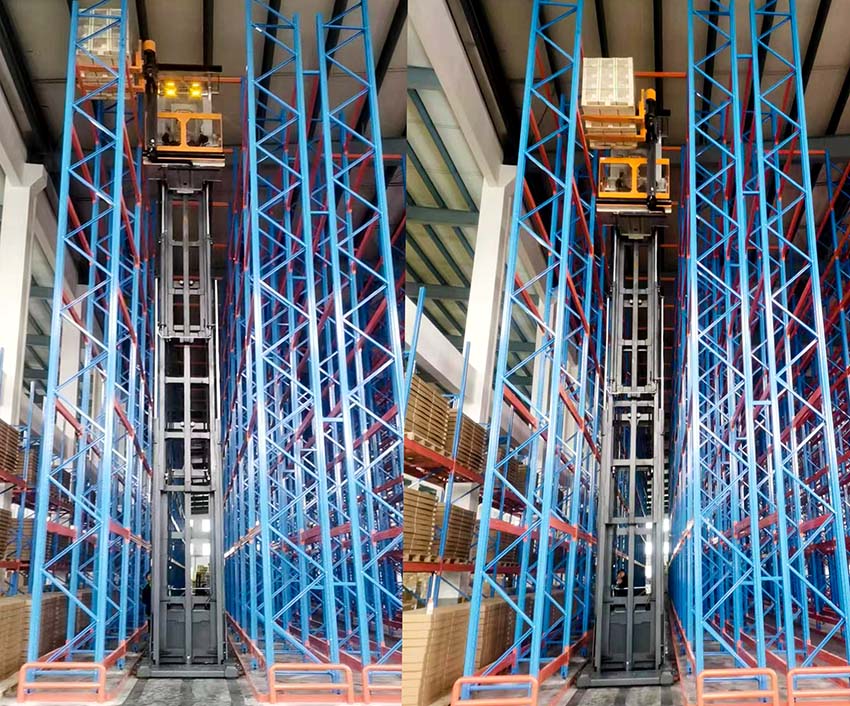

After surveying the site and gaining an in-depth understanding of the working conditions and the needs of the enterprise, the person in charge of the Zowell intelligent forklift project provided a very narrow aisle stacking solution, using VNA man down type three-way forklifts to help the enterprise's logistics upgrade.

1. Standard configuration of three-way electric fork for man up type VNA forklift, one-button linkage for rotation/side movement, and the reversing time of ordinary hydraulic fork is more than 30s. Using Zowell patented three-way fork can be completed in less than 10 seconds; The stacking efficiency has more than doubled to meet the demand for high throughput of goods.

2. Man up type VNA forklift support walking + the cab is lifted and lowered synchronously, which provides a new idea for picking when there are many SKUs in the enterprise and the picking demand is large. Picking + stacking kills two birds with one stone, while reducing equipment purchase costs.

3. Zowell's maximum lifting height is 13.5m. Under the suggestion of Zowell's staff, the company can increase the height of the shelves and fully release the available space at the high places to complete the upgrade of storage density.

4. Guide rails are installed at the aisle of the shelves, and the forklifts drive along the guide rails in the narrow aisles to prevent safety accidents caused by collisions with the shelves when walking and accessing goods.

The development of the manufacturing industry is inseparable from the upgrading of logistics. The efficiency of entering and leaving the warehouse has been improved + the storage efficiency has increased significantly + the investment cost is low. The logistics solution provided by Zowell intelligent forklift successfully helped the company solve the logistics problem, strengthen the warehouse turnover efficiency, and realize the timely supply of production materials, thereby further improving the order completion. speed.

In the future, Zowell intelligent forklift will continue to update logistics products, accumulate technical experience, provide one-stop intelligent logistics solutions for the logistics field of various enterprises, and help major industries develop steadily.