Recently, Zowell's VNA forklift stacking solution for extremely narrow aisles has successfully landed in an international leading cosmetics company.

Client background

The client is the creator of the international beauty industry, dedicated to the R&D and production of cosmetics, and has more than 1,000 international cooperative brands. Based on the development needs of the enterprise, the upgrading of the traditional logistics system has become a project to be solved by the enterprise.

Zowell Intelligent Forklift provided four sets of three-way VAN forklifts + three reach trucks to help the company get rid of logistics problems.

The low-carbon and environmentally-friendly logistics system realizes the improvement of inventory space and operation efficiency by reducing costs, increasing efficiency, and meeting the needs of the high-speed business development of the cosmetics company.

Project difficulties

1. There are many types of cosmetics, with SKUs ranging from hundreds to thousands, and each product contains multiple SKUs. Due to the impact of production batches and shelf life, it is necessary to quickly select and first-in-first-out when leaving the warehouse;

2. Cosmetic products have extremely strict requirements on the temperature and air cleanliness of the storage environment;

3. Affected by marketing, activities, and brand power, it is not uncommon for warehouses to be liquidated, so it is extremely challenging for storage space and storage costs;

4. Cosmetic goods are high in value, small in size, irregular in shape, fragile and easy to leak, and have extremely high requirements on transportation stability.

Project highlights

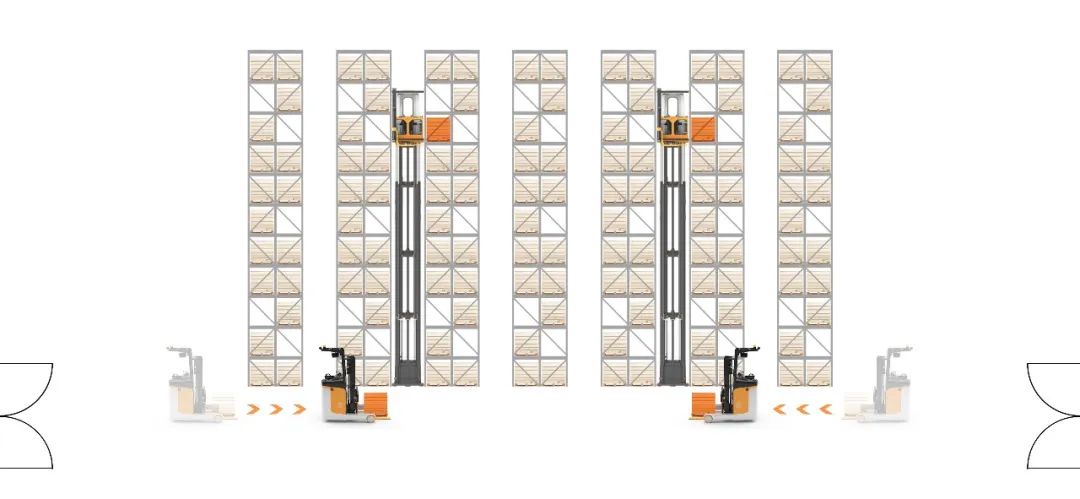

Zowell intelligent forklift has rich experience in logistics and warehousing of the whole industry. After in-depth understanding of the warehousing and picking mode of cosmetics companies, Zhuoyi provides a complete logistics operation plan (reach truck + man up VNA three-way forklift). While reducing logistics operation costs for the enterprise, it can realize efficient docking of loading, unloading and stacking + improvement of sorting efficiency.

1. The operator chooses to stack up three-way forklifts, and unloads with reach trucks, according to the first-in-first-out batches with expiration dates.

The three-way electric fork head that is standard for VUE model can complete the 180° rotation of the fork in less than 10 seconds, and lightly change direction in the 1.6m roadway to take the goods on both sides, which greatly improves the asset turnover efficiency;

2. Zowell’s products are all electric, and there is no exhaust emission during the operation process, which can ensure that the warehouse is clean and dust-free, and the cosmetics are not polluted.

3. On the basis of no change in the site, increase the height of the shelves, increase the quantity of inventory, and make good use of the warehouse space to the greatest extent. For complicated SKUs, the storage area is divided to avoid stacking and mixing of goods, and to improve the overall decomposition efficiency of goods with relatively low operating costs.

4. Integrated handle to control vehicle, the operation is more precise, the driving is more stable, and the cosmetics are not easy to dump and damage during the transportation and stacking process, reducing damage.

The investment in Zowell's logistics solutions will help enterprises optimize their real warehouse space, improve the efficiency of picking out and entering warehouses, complete customer orders accurately and efficiently, and improve customer satisfaction.