15.07.2023

Standard Work|Zowell Intelligent Forklift Successfully Hosts Industry Standard Expert Validation Meeting

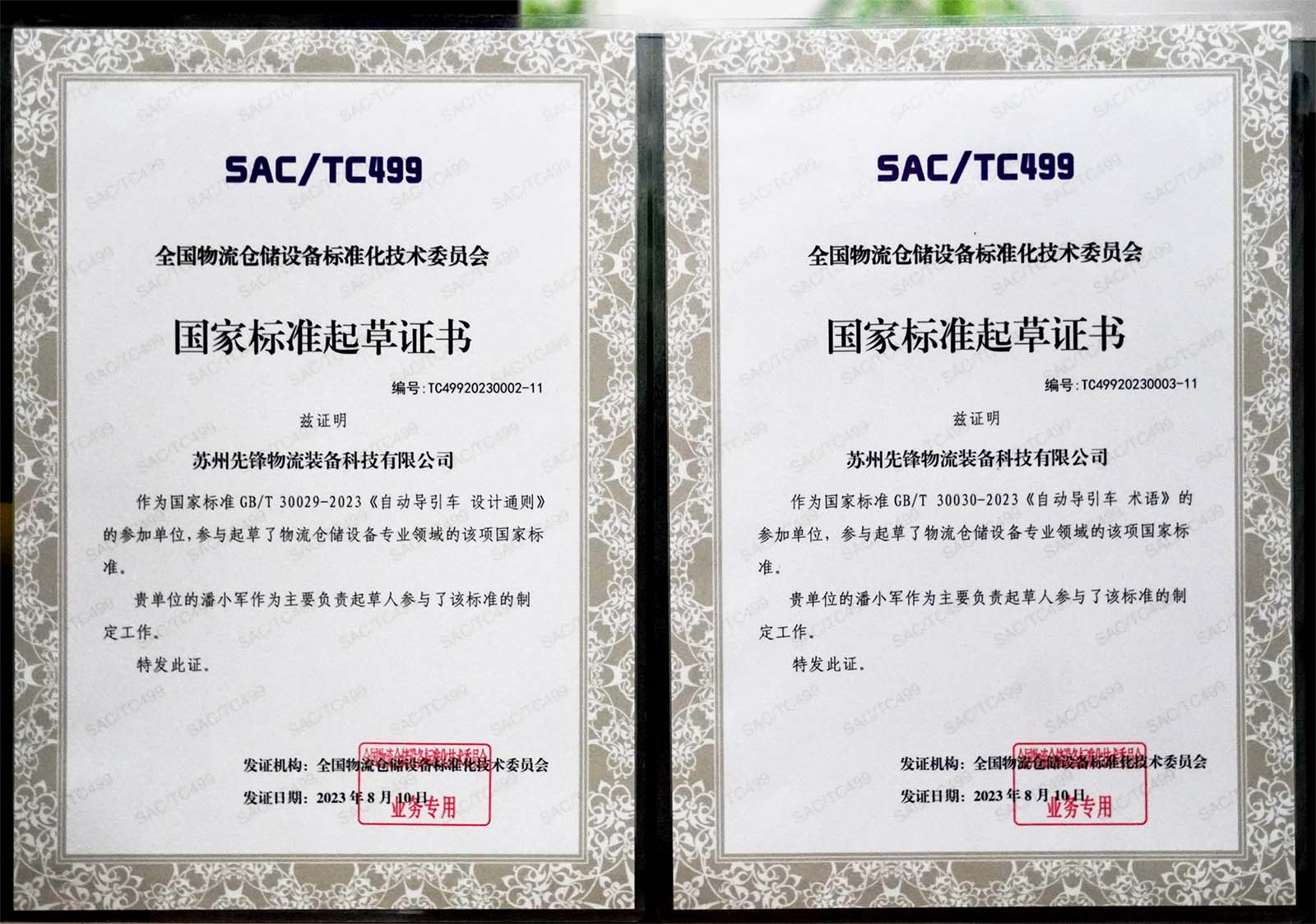

From July 12 to July 14, 2023, the expert validation meeting for the two industry standards of "Three-way VNA Forklift" and "Multi-directional Forklift", which were organized by the National Technical Committee for Standardization of Industrial Vehicles (NTCSIV), was held in Suzhou, Jiangsu Province, which is a beautiful city in China. As a participant in the formulation of the two industry standards, Zowell Intelligent Forklift was entrusted by the Standardization Committee to undertake this meeting. Ms. Zhao Chunhui, Secretary General of National Technical Committee for Standardization of Industrial Vehicles, Mr. Fan Hengman, Senior Engineer of National Quality Inspection and Testing Center for Lifting and Transportation Machinery, and representatives of famous domestic enterprises such as HELI, HANGCHA, LINDE, Jungheinrich and so on, a total of 16 technical experts attended the meeting. The meeting was hosted by Ms. Zhao Chunhui, Secretary General of Industrial Vehicle Standard Committee. At the beginning of the meeting, Mr. Pan, General Manager of Zowell Intelligent Forklift, delivered a sincere speech on behalf of the contractor. As a 30+ years forklift veteran, Mr. Pan expressed the importance of the development of the two industry standards "Three-way VNA Forklift" and "Multi-directional Forklift" in the construction of the product quality system and the future participation of enterprises in the international competition, and lastly, he expressed his warm welcome and heartfelt thanks to the arrival of the experts for the standard validation. According to the schedule, after Mr. Pan's speech, the meeting entered into an intense and orderly discussion of the standard terms and conditions of the validation session. At the meeting, the experts expressed their views, and with international standards and domestic existing standards closely linked to the integration of the "Three-way VNA Forklift" and "multi directional forklift" two industry standards (draft) chapter by chapter, article by article, and rigorous validation, and strive to achieve rigorous and professional professional in terms of professionalism, technicality, practicality, guidance, etc., highlighting the authority of the standard-setting work. After 1.5 days of opinion summarization and discussion, and finally on the basis of the consensus of the participating experts to form the "two-way and multi-directional forklift", "Three-way VNA Forklift" two industry standards for review and approval, the agenda of the meeting was successfully completed. In recent years, the development and establishment of Zowell Intelligent Forklift in the field of narrow aisle forklifts have been highly concerned and recognized by the industry. This time, the successful participation in the formulation of two industry standards for narrow aisle forklifts, namely "Two-way and Multi-directional Forklift" and "Three-way VNA Forklift" and the hosting of the related conference work, is a test and an affir...

Read More